The National Automotive Design and Development Council (NADDC ) has dismissed insinuations that the Federal Government may have jettisoned the National Automotive Policy owing to the worrisome situation of the Nigerian economy at the moment, saying the Federal Government was still committed to the policy.

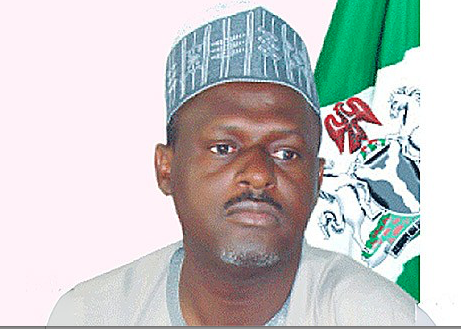

NADDC Director General, Engr. Aminu Jalal, who restated the Federal Government’s commitment to the Auto Policy , dismissed the insinuation that the policy may have been abandoned, describing such insinuation as baseless and unsubstantiated. He said the Federal Government had already resolved to substantiate the policy initiative as part of its efforts to empower the automotive industry as viable alternative to oil.

Jalal spoke in Lagos at the just-concluded Manufacturing & Equipment Expo, Nigeria 2017 where he delivered an audio visual driven thesis titled: ‘How to make Nigeria Africa’s leading automotive hub.”

According to Jalal, “It is already assured that the new government will continue with the policy, and the response so far has exceeded our expectations. Our emphasis as it is has shifted to the development of automotive component.”

He disclosed that five South African companies have indicated interest in establishing component manufacturing plants in the country just as some Chinese investors have similarly indicated interest in exploring opportunities in the nascent auto industry.

It must be noted that the Nigerian automotive industry is designed to ensure survival, growth and development of automotive manufacturing, using local human and material resources with a view to enhancing the industry’s contribution to the national economy, especially in the areas of transportation of people, goods and services.

Jalal said no fewer than 14 assembly plants (with more being established) have since 2014 began operations, assembling new products including cars and SUVs like Nissan, IVM, Peugeot, Hyundai, Honda, Kia, Volkswagen, Ford, Changan and GAC.

He noted that in the bus and trucks category, Hyundai, Ashok-Leyland, MAN, Anammco, Leyland-Busan, IVM, FAW, Sino, Shacman, Aston, Foton, Forland and Isuzu are among notable brands currently being produced at various facilities in Nigeria, stressing that Proforce Limited, which produces armoured vehicles, now has an installed capacity for over 300, 000 units annually.

Jalal said these plants, in 2015, contributed 75, 000 units of vehicles including concessionary imports, representing 75 per cent of estimated 100,000 new vehicles that made it into the market during the period under review.

He also added that the industry is long-term in nature and requires policy continuity and constituency, saying Nigeria is on track to becoming a vehicle manufacturing nation.

His words : “The Nigerian automotive development plan is our best chance of developing this vital industry and making Nigeria Africa’s leading automotive hub, especially when viewed against the market potential of the ECOWAS and Central African countries estimated at one million vehicles annually.

“One of the convictions of the National Automotive policy is to have vehicle assembly operations with increasing local content absorption that could evolve from one stage to another, for instance from SKD2 (semi-knocked down) to CKD (completely knocked-down) operations without exceeding 12 months or maximum of 36 months, including a set-up period of 12 months.”

He referred to the institutional framework as validated in article 5.1 of the National Automotive Policy, which states inter alia “There will be phased component parts deletion programme for cast, pressed and forged body and mechanical parts and trim/accessories with the establishment of relevant engineering infrastructures. And in item 6.1, “Local and foreign investors shall be encouraged to establish automotive vehicles and component parts outfits.”

The NADDC director general said the biggest multiplier effect of automotive manufacturing comes with component manufacturing, saying the more you localise, the higher the number of jobs created, and the deeper you go downstream, the more jobs you create.

“Assembly operations alone account for about 15 to 20 per cent of the cost of the vehicle. When you add local content, you now increase the value added, “ he said, adding,”We are hoping that within the next five years, we will reach value addition of about 30 to 40 per cent.’’

The Nigeria automotive industry is valued at USD$2trillion annually with diverse scope for manufacturing agriculture, defense, power generation, marines and aircraft engines.

..:: AUTO REPORT AFRICA ::..

..:: AUTO REPORT AFRICA ::..